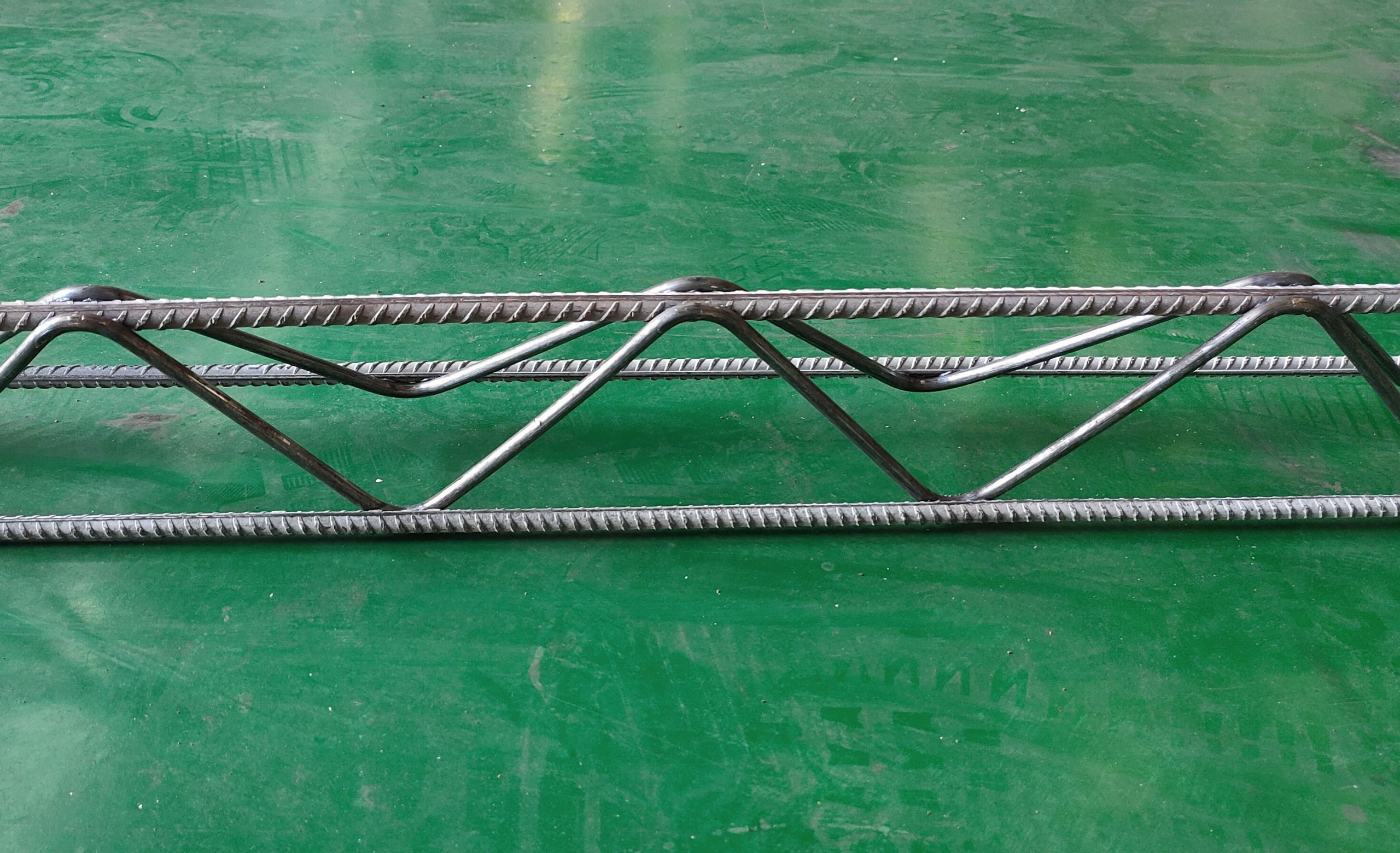

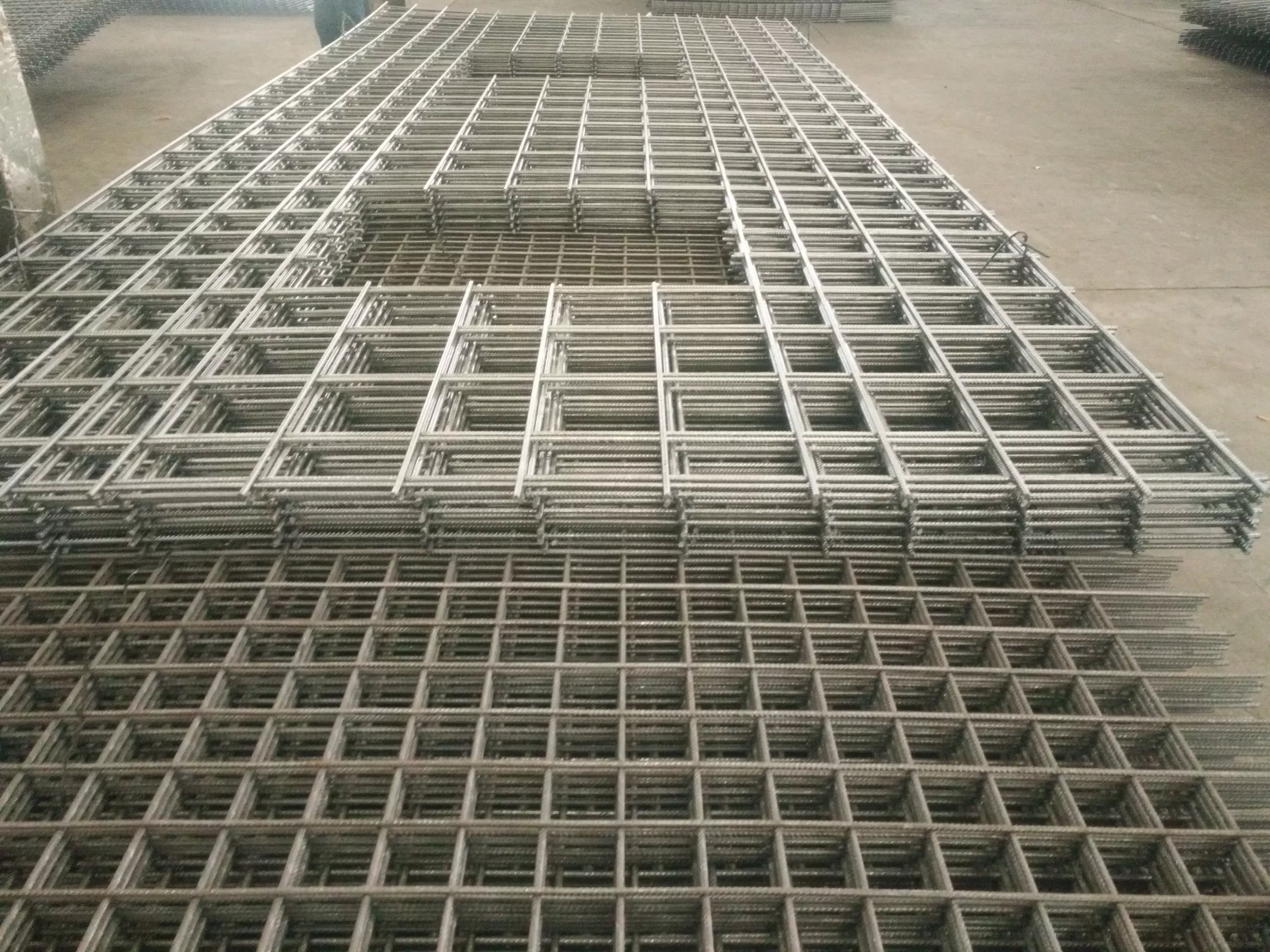

Welded Steel Mesh / Fabric

Definition:

Longitudinal and transverse bars of the same or different diameter and length, which are arranged substantially at right angles and factory electrical resistance welded at the points of intersection and rely on the shear strength of the welds for lapping sheets.

Parameters:

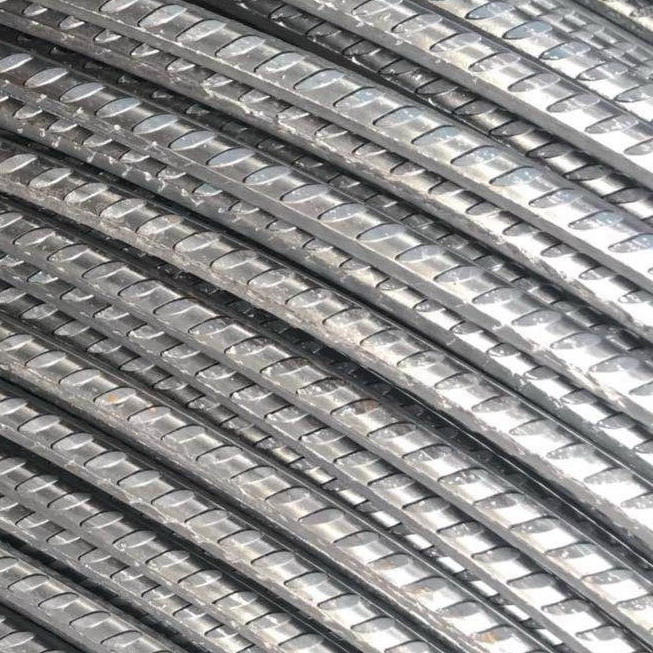

- Material: Cold-rolled ribbed bars/ plane bars to respective standards,

- Diameter: 5mm~12mm,

- Interval: 100mm/ 150mm/ 200mm/ 250mm, custom size negotiable,

- Size: length≤12m, width≤3m, subject to shipping restrictions,

- Properties: to respective production standards.

- Australian Mesh:SL62/ SL72/ SL82/ SL92/ SL102/ SL81/ RL818/ RL1018/ RL1218 for AS/NZS 4671 Standard.

Production Standard:

1. GB/T 1499.3-2022, Steel for the reinforcement of concrete - Part 3: Welded fabric (Chinese),

2. AS/NZS 4671:2019, Steel for the reinforcementof concrete (Australian/New Zealand),

3. BS 4483:2007, Steel fabric for the reinforcement of concrete - Specification (British),

4. ISO 6935-3:2023, Steel for the reinforcement of concrete - Part 3:Welded fabric (International),

5. Other standards negotiable.

- Material: Cold-rolled ribbed bars/ plane bars to respective standards,

- Diameter: 5mm~12mm,

- Interval: 100mm/ 150mm/ 200mm/ 250mm, custom size negotiable,

- Size: length≤12m, width≤3m, subject to shipping restrictions,

- Properties: to respective production standards.

- Australian Mesh:SL62/ SL72/ SL82/ SL92/ SL102/ SL81/ RL818/ RL1018/ RL1218 for AS/NZS 4671 Standard.

inquiry

Short Description

The concept of welded steel mesh / fabric was first proposed in 1901, while the first major application was in 1908. In 1922, it was tested to be the sufficiently suitable material for roads of heavy traffic. By the close of World War II, it showed its strength because it requires less labor and time. It was seen as the perfect reinforcing material to help Europe re-build after the war. Before the turn of the century, it was accepted as a viable form of concrete reinforcement in building. It has also enjoyed great usage in other projects like airport runways and a number of architecturally groundbreaking buildings.

Advantages

1. Better

1.1 Improve the Quality of Structure

It is machine welded in the factory, the spacing of steel bars is accurate, and the sheet is a whole piece which redenrs better and reliable bond with concrete. It can also prevent the steel fixers from cutting corners by increasing the distance between the bars, which is conducive to improving the quality of the project when welded steel mesh / fabric is used.

1.2 Higher Steel Strength

Compared to manually fixed rebar, welded steel mesh / fabric made from high-quality low-carbon steel wire through cold-rolling is of higher strength, normally of 500Mpa.

1.3 Better Anti-cracking Performance

Welded steel mesh / fabric in concrete can prevent cracks in wall and floor slabs. This is because when a wall or floor slab shrinks or is pulled, the steel resists these tensile stresses and welded steel mesh distributes the stress evenly over a large area, helping them to hold tightly together and thus minimize cracks.

2. Cheaper

2.1 Save Labor Costs

With welded steel mesh / fabric, the site process of drafting, marking, cutting and laboriously tying of rebars is saved, contractors can save a lot of labor costs.

2.2 Save Site Equipments Cost

When welded steel mesh / fabric is used, the contractors save steel bar straightening and cutting equipments cost which is normally a major cost for the contractor.

2.3 Comprehensive Benefits

Designers do not need to enlarge the insurance factor to prevent dishonest construction practices and ensure the quality of the structure. Therefore, the hidden cost of the investors and contractors can be reduced.

3. Faster

With welded steel mesh / fabric, the steel fixing process is simple and the construction speed is greatly improved.

4. Safer and Environment Friendly

On site manual cutting and bending operation is much less, reducing the safety risks, noise and pollution, conducive to environmental protection to the surrounding environment.

Application Fields

Welded steel mesh / fabric has been widely adopted in the construction industry, not only for prefabricated concrete components, but also applied more frequently to cast-in-place concrete structures, such as:

1. Transportation Industry

Highway deck pavement, concrete pavement for soft ground sections, base plates of high-speed rail tracks, surface crack prevention on bridge piers, concrete ground for toll plazas, concrete ground for railway platforms, stations, and cargo areas, concrete ground for airport runways, cargo areas, and parking lots, tunnel lining, etc;

2. Municipal Engineering

Municipal bridge and overpasse's deck pavement, concrete pipe galleries, drainage channels, underground culverts, fences, slope protection, etc;

3. Water Conservancy, Electricity, Mining

Water conservancy facilities, dams, wharfs, ports, electric power engineering foundations, shotcreting and bolting support in mines, etc;

4. Building Industry

Multi-story and high-rise industrial and civil buildings (floors, roofs, walls), etc. In recent years, welded steel mesh / fabric has also been commonly used in Prefabricated buildings to replace manual fixing to improve production efficiency;

5. Others

Flood control facilities, slope reinforcement, collapse protection, etc.

You may also want to know about

the following products

-转-scaled.jpg)