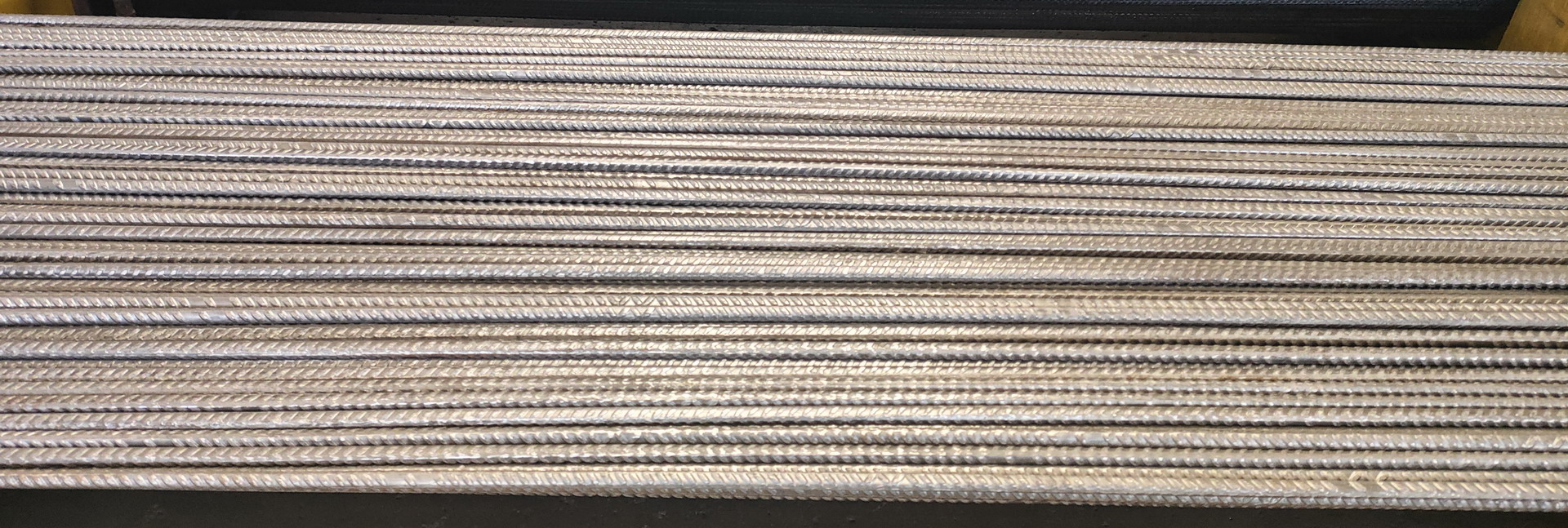

Cold-rolled Ribbed Bars

Definition:

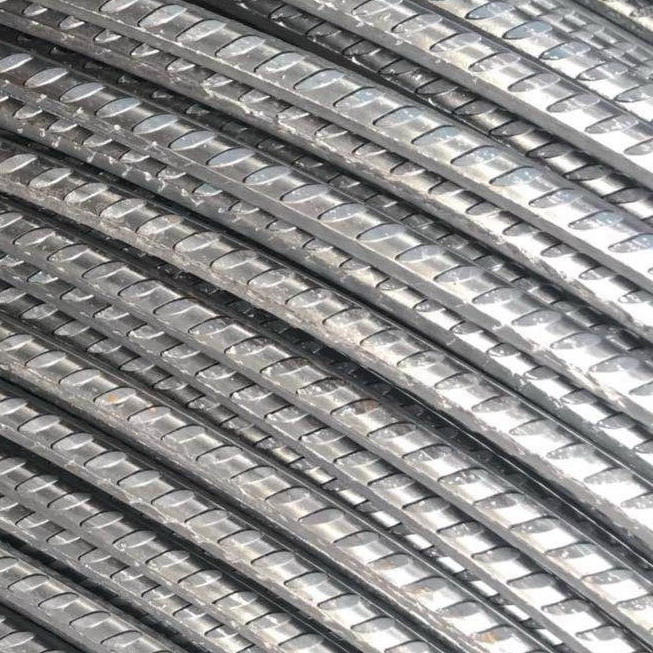

Cold-rolled ribbed steel bars are made from hot-rolled round wires through cold-rolling, with uniformly distributed transverse ribs on the surface alongside the length direction.

Parameters:

- Material: CRB550/ CRB650/ CRB800/ CRB600H/ CRB680H/ CRB800H,

- Diameter: 5~12mm for CRB550/ CRB600H/ CRB680H,

- 4,5,6mm for CRB650/ CRB800/ CRB800H,

- Length: ≤12m (Transportation restriction)

Production Standard:

GB/T13788-2017, Cold rolled ribbed steel bars (Chinese),

Other standards negotiable.

- Material: CRB550/ CRB650/ CRB800/ CRB600H/ CRB680H/ CRB800H,

- Diameter: 5~12mm for CRB550/ CRB600H/ CRB680H,

- 4,5,6mm for CRB650/ CRB800/ CRB800H,

- Length: ≤12m (Transportation restriction)

inquiry

Short Description

Cold-rolled ribbed bar is mainly a middle product for the manufacturing of welded steel fabric/ mesh, but we also see its application in some projects to substitute conventional steel bars or as prestress concrete reinforcement.

Advantages

1. Save Steel Consumption

Normally cold-rolled ribbed bars have higher strength than hot-rolled wires, so it can save steel consumption in some cases, that's why we see its application in some projects to substitute conventional steel bars or as prestress concrete reinforcement.

2. Welding Friendly

Cold-rolled ribbed bars are easier for mesh-welding compared to hot-rolled ribbed bars because there are no longitudinal ribs alongside the length of the bar which adversely affect the connectiveness of the logitudinal bars and the cross bars.

Application Fields

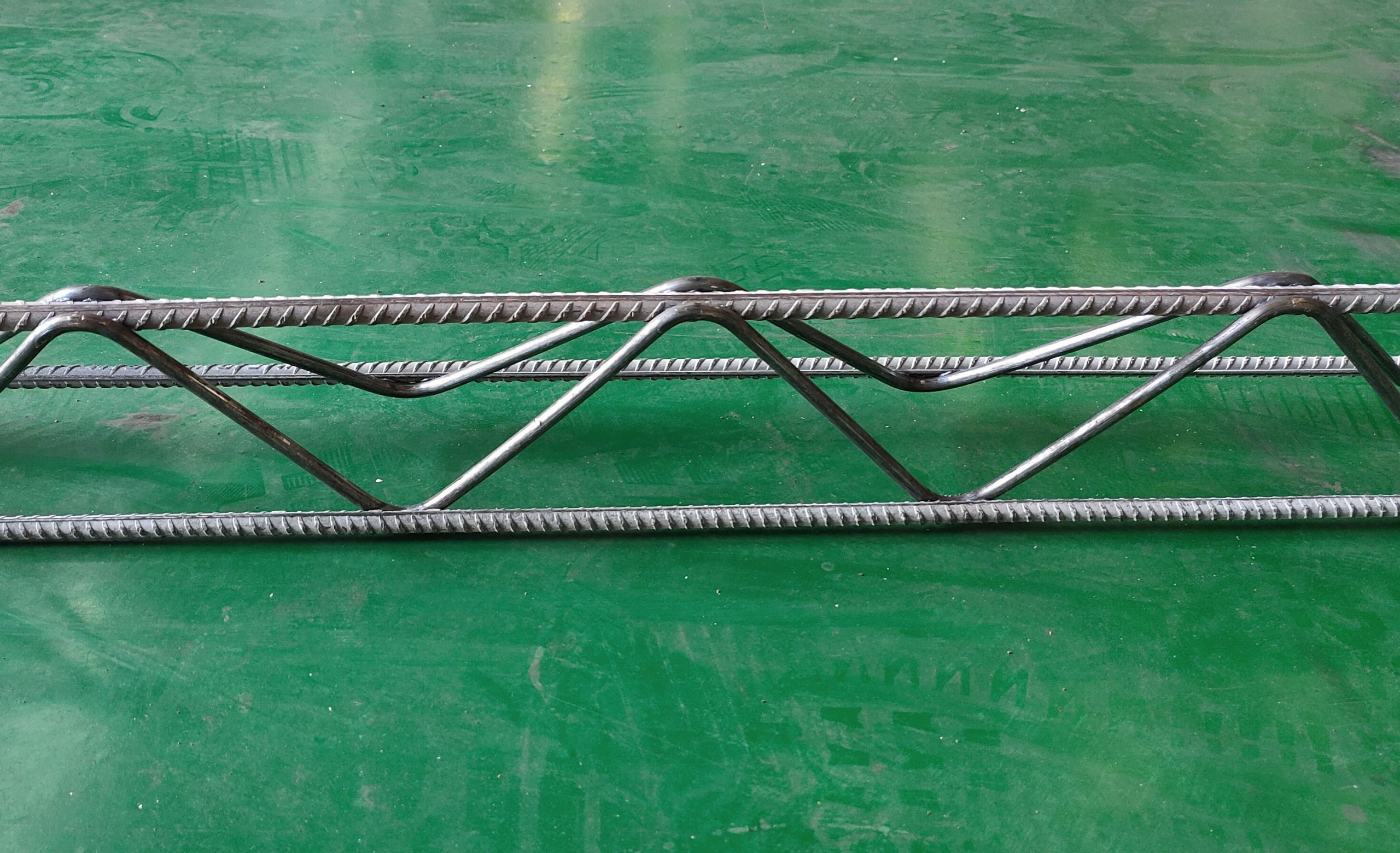

1. Welded Steel Fabric/ Mesh

Cold-rolled ribbed bars are mainly used as longitudinal and cross bars of welded steel fabric/ mesh, connected through resistance welding.

2. Building Engineering

Cold-rolled ribbed bars are much higher in strength, so some contractors use CRB550/ CRB600H/ CRB680H in the slabs of the building to substitute conventional steel bars to save steel consumption.

3. Prestress Concrete Reinforcement

CRB650/ CRB800/ CRB680H/ CRB800H cold-rolled ribbed bars are often used in prestress concrete components such as slabs of the building or prestressed power poles.

You may also want to know about

the following products